Ngwaahịa

Ahịrị nrụpụta fatịlaịza Organic

Nkọwa ngwaahịa

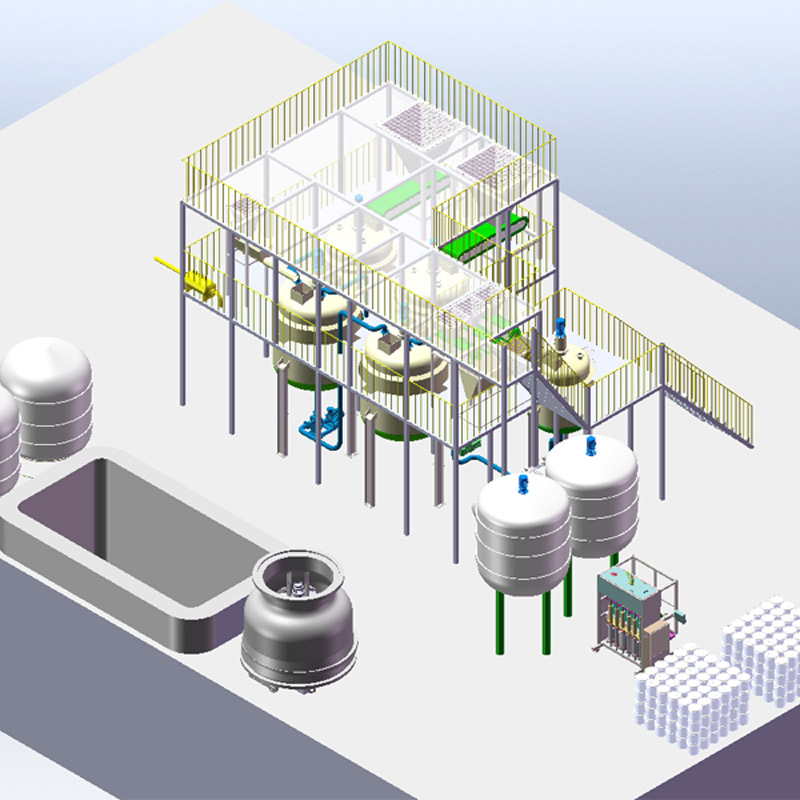

A na-ejikarị osisi na-emepụta fatịlaịza organic na-edozi ihe dị iche iche fermented organic n'ime fatịlaịza organic. Ọ na-anabata teknụzụ ịkpụzi otu nzọụkwụ.A na-emegharị nri anụmanụ na ihe mkpofu nke ugbo dị ka isi akụrụngwa, mmepe nke ahịrị imepụta fatịlaịza organic na usoro ịgba ọgwụ mgbochi ọrịa site na iji anụ ụlọ na nri anụ ọkụkọ.Ọ ga-akwalite nke ọma mmepe nke ọrụ ubi na gburugburu ebe obibi akụ na ụba.

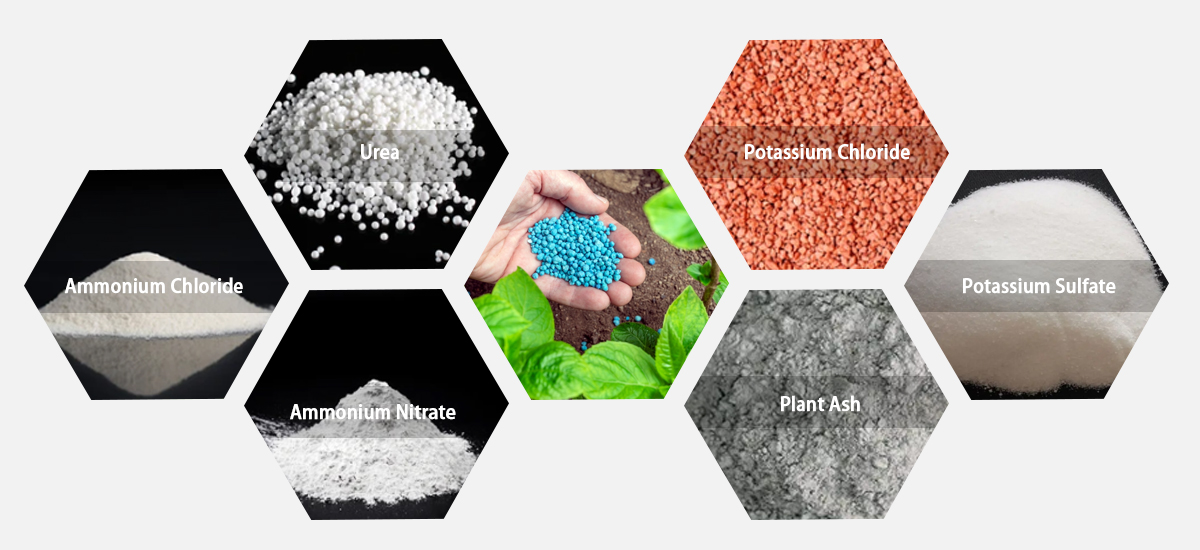

Akụrụngwa nke ahịhịa na-emepụta fatịlaịza organic:

1. Ihe mkpofu ugbo: ahihia, ogwu agwa, mkpuru owu, osikapa, wdg.

2. Nri anụmanụ: Ngwakọta anụ ọkụkọ na ihe mkpofu anụmanụ, dịka mkpofu ụlọ anụ, ahịa azụ, mmamịrị na nsị ehi;

Ezi, atụrụ, ọkụkọ, ọbọgwụ, anụ ọhịa, ewu, wdg.

3. Ihe mkpofu ụlọ ọrụ: mmanya mmanya, ihe fọdụrụ na mmanya, ihe mkpofu manioc, sugar scum, furfur residue, wdg.

4. Mpekere n'ụlọ: mkpofu nri, mgbọrọgwụ na akwụkwọ nri, wdg.

5. Sludge: sludge nke osimiri, ọwa mmiri, wdg.

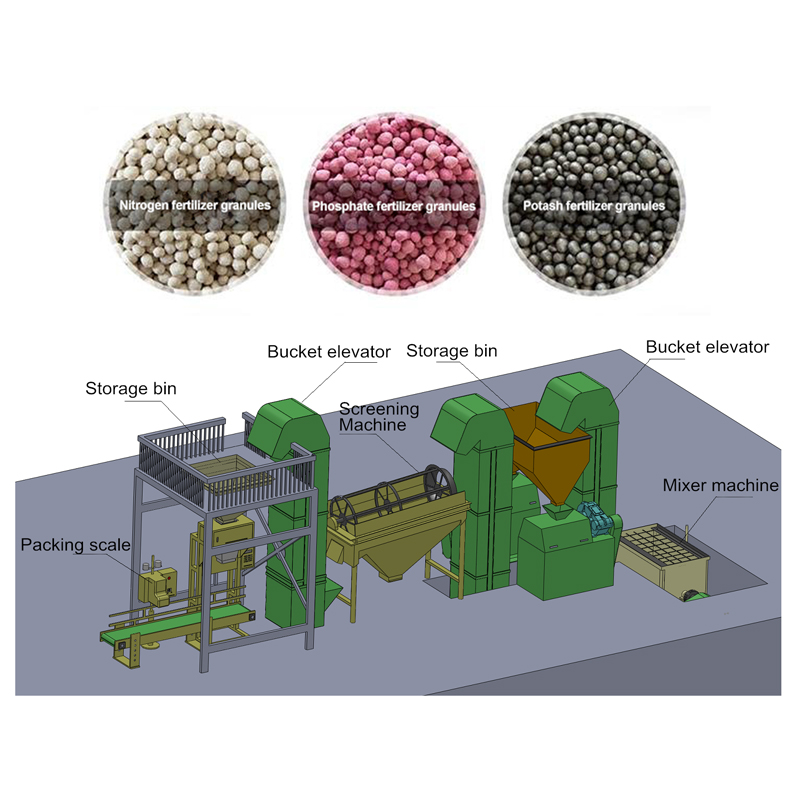

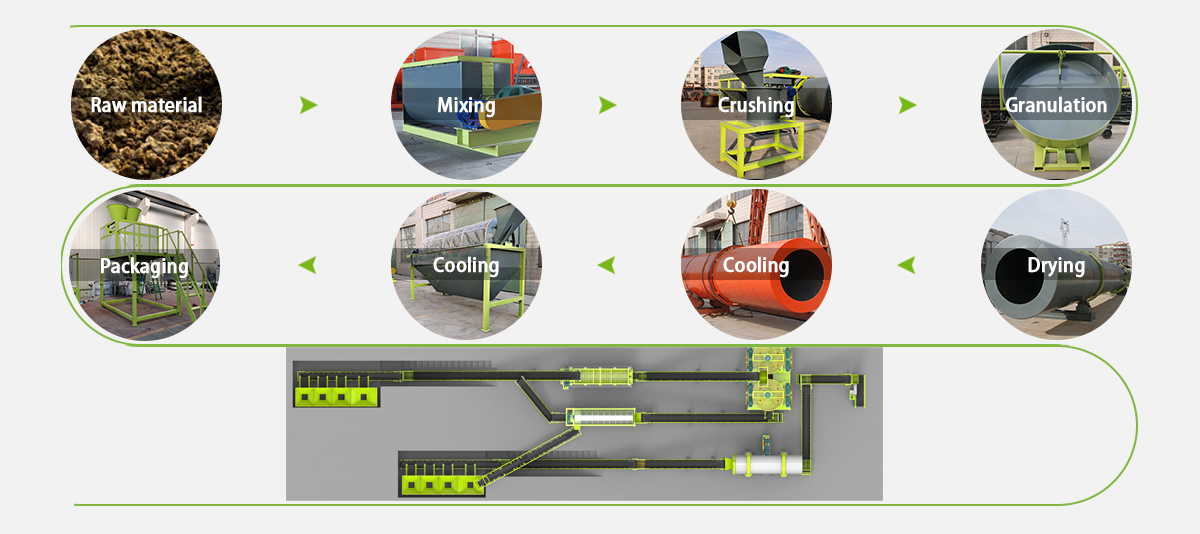

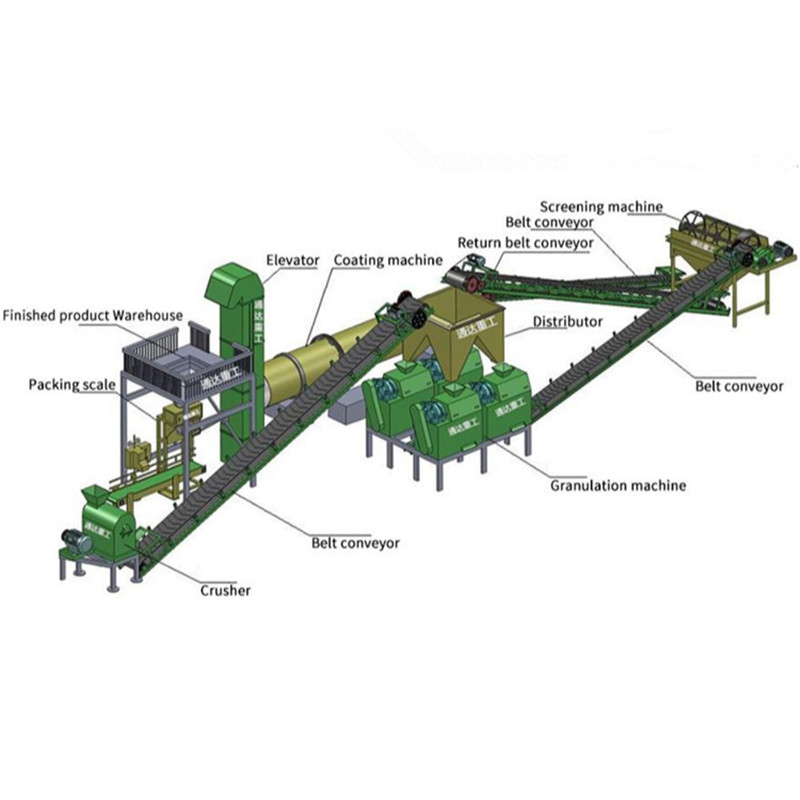

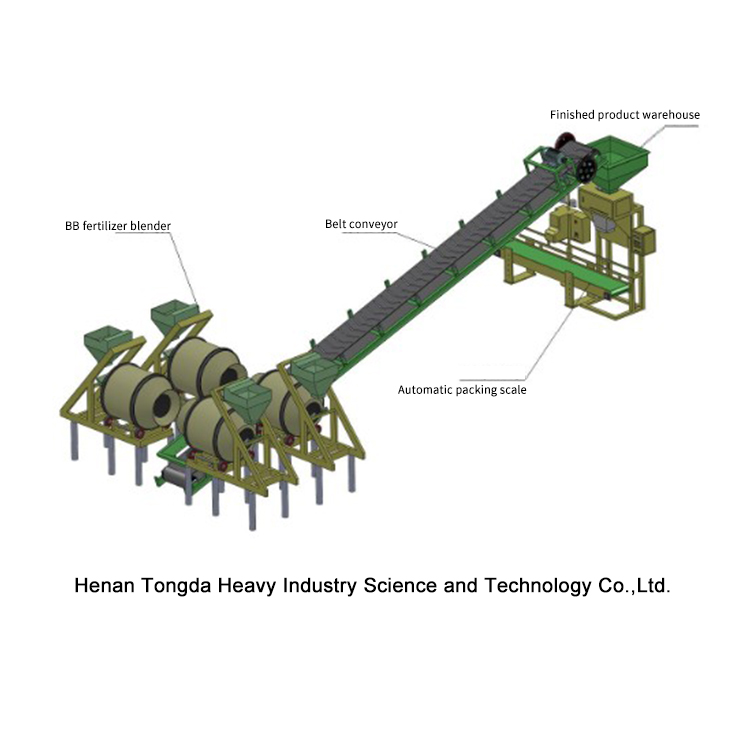

The dum organic fatịlaịza mmepụta ahịrị na-agụnye ndị na-esonụ igwe: raw material gbaa ụka → Fatịlaịza na-egwepịa igwe → igwe agwakọta fatịlaịza → fatịlaịza rotary drum granulator → fatịlaịza rotary drum granulator → fatịlaịza rotary drum ihicha / igwe oyibo → fatịlaịza rotary drum mkpuchi igwe → ebufe eriri → na ngwa ndị ọzọ.

1.Organic ihe gbaa ụka usoro na-arụ nke mbido ma dị mkpa ọrụ dum fatịlaịza mmepụta akara.A na-eji ụdị ntụgharị compost abụọ bụ isi n'ọtụtụ ebe iji tụgharịa na ịgwakọta compost ma mee ka ọsọ gbaa ụka sie ike: Turner compost nke na-ebupụta onwe ya na ihe ntụgharị compost hydraulic.

2.Crushing usoro: The compost akpụ ihe kwesịrị ịbụ ala tupu usoro granulating.Mana anyị nwere ike ịhapụ usoro ịzọpịa mgbe ihe compost dị mma.Vetikal yinye crusher na okpukpu abụọ-ogwe kehoraizin crusher, ụdị abụọ nke igwe-etipịa nwere ike iji gwepịa akpụ compost fatịlaịza akụrụngwa.

3.Mixing usoro, a na-etinye ụdị abụọ nke igwe na-ejikọta ihe eji eme ihe na-emepụta ihe na-emepụta ihe na-emepụta fatịlaịza: Igwe ọkụ kwụ ọtọ na igwekota vetikal.

4.Ihicha usoro.Mgbe fatịlaịza granulating, mmiri nke fatịlaịza akụrụngwa kwesịrị ịbụ ihe na-erughị 25%, ya mere, anyị kwesịrị nkụ nke akụrụngwa ma ọ bụrụ na mmiri karịrị 25%.Rotary drum ihicha igwe na tumadi ji maka ihicha fatịlaịza na ụfọdụ ogo iru mmiri na urughuru size.

5.Fertilizer granulator usoro.Granulating usoro bụ isi akụkụ na nke a mmepụta ahịrị, n'ihi ya, anyị na-ahọrọ ndị kwesịrị ekwesị nlereanya nke fatịlaịza granulator dị ka ndị ahịa zuru ezu chọrọ.Optional granulator akụrụngwa: Organic fatịlaịza Nchikota granulator, organic fatịlaịza pụrụ iche granulator, ụzọ mpịakọta extrusion granulator, diski granulator, ewepụghị film. granulator, bio organic fatịlaịza spherical granulator, drum granulator, gburugburu tossing igwe, wdg;ngwa ngwa ngwa: nri ọkụkọ, nsị ehi, kaolin, wdg.

6.Rotary drum jụrụ igwe na-eji maka oyi fatịlaịza na-eme ka fatịlaịza ahụ ike.

Usoro nyocha 7.Screening: A na-eji igwe na-enyocha ihe nkiri Rotary iji kewaa granules site na nnukwu ihe dị mkpa ka a weghachite maka nke abụọ na-egwepịa na granulating.A na-eji igwe mkpuchi rotary drum kpuchie fatịlaịza ma gbochie fatịlaịza ịrapara ọnụ.

8. Usoro ikpeazụ bụ usoro nkwakọ ngwaahịa.Igwe nkwakọ ngwaahịa fatịlaịza nwere ike ịkwakọba akpa n'ọnụ ọnụ yana na-akpaghị aka.Gụnyere eletrọnịkị quantitative packaging scale.Ọ chọkwara ụfọdụ ngwa inyeaka maka njikọ dịka ebufe belt, mbuli elu ịwụ, wdg.

Nrụpụta dị elu:

Usoro niile na-arụ ọrụ na-akpaghị aka. Ọrụ dị mfe, naanị mmadụ abụọ nwere ike ịrụ ọrụ.

Ọnụ ego arụ ọrụ dị ala yana oriri ume dị ala:

Enwere ike ịhazi ụdị nri anụmanụ niile.4 awa ndụ deodorization.Ichekwa ume ọkụ na-ekpofu ọkụ na nchedo gburugburu ebe obibi.Kwesịrị ekwesị maka nnukwu, ọkara na obere ugbo.

A na-eji ọtụtụ ngwaahịa emechara:

Ugbo ezì, ugbo ehi, wdg .. Ngwa nke ụdị nri compost fatịlaịza igwe na-emepụta fatịlaịza nwere ezigbo uru maka nchekwa gburugburu ebe obibi.